Services

LPG Cylinder Plant

LPG cylinders are manufactured in absolute compliance with NIS69-2013 Standards using the latest technology with automated cutting-edge machineries and in many different sizes ranges from 3kg to 12.5kg according to clients demand and specification. The production process consists of seven steps:

02.

2. Welding Line

Zen Ltd uses world renowned welding machine and consumables that ensure the safety o….

03.

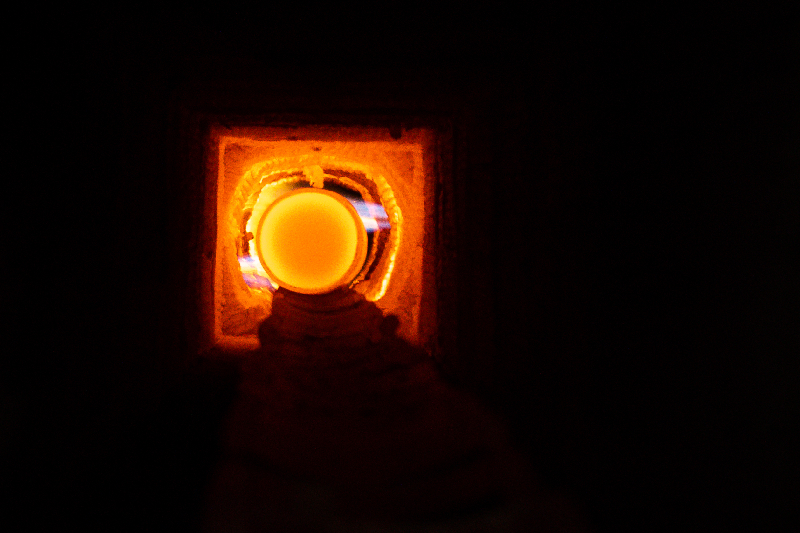

3. Heat Treatment

To remove residual stress developed during deep drawing and welding operation, c….

04.

4.Hydrostatic Test

Hydrostatic test is carried out for checking cylinder integrity and leak at 34 b….

05.

5. Shot Blasting

During the heat treatment, operation scales & rusts are gathered on the surface ….

06.

6. Painting Line

Robotic paint application system is used for painting of cylinders followed by o….